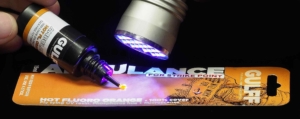

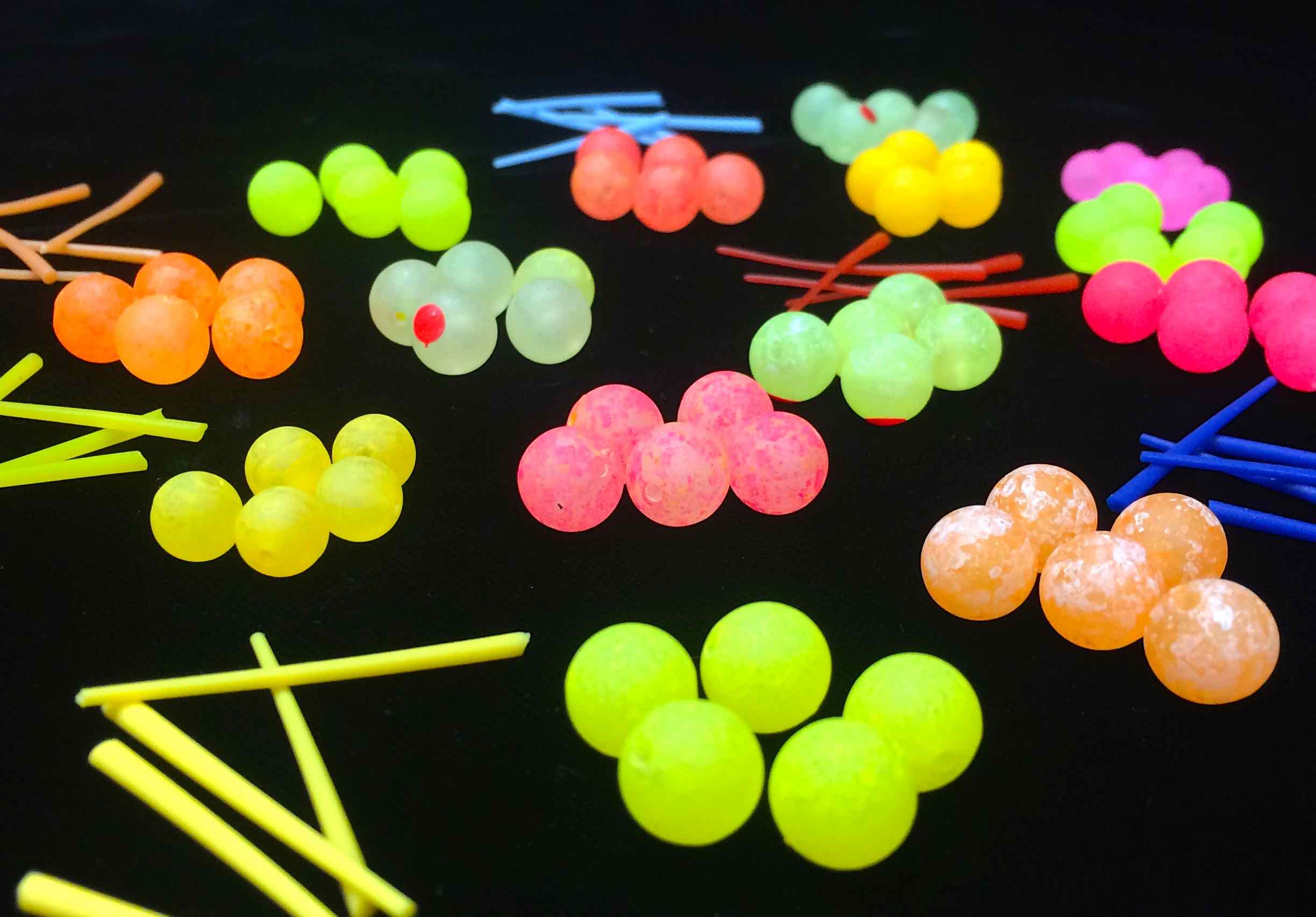

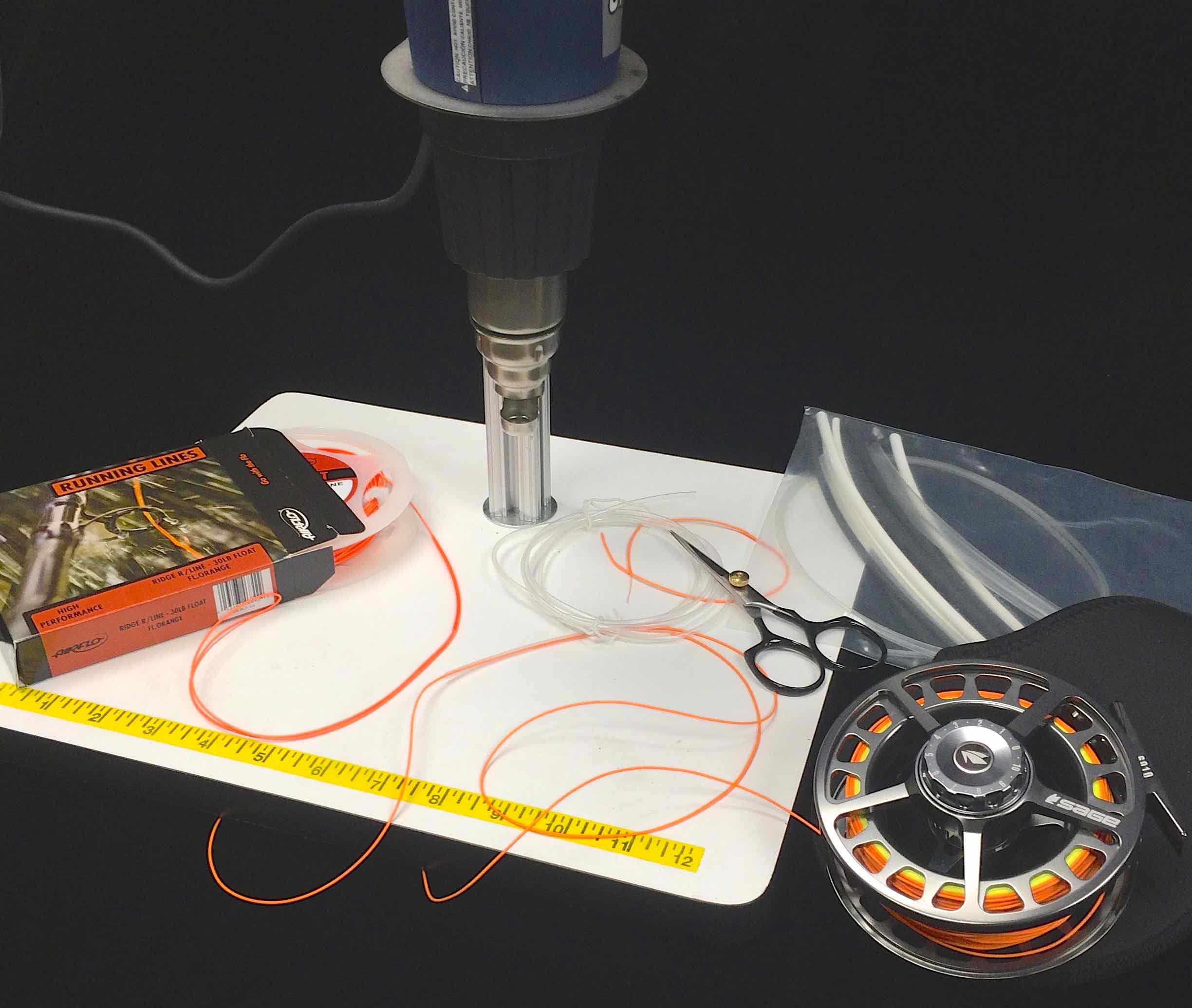

TFC’s UV Light Sabre is a inexpensive UV light that is ideal for checking out our HLS Custom UV Bead line up, or used for curing UV resins like the Loon UV Finishes , GULFF UV Resins or the Solarez UV Resin Product Line up.

Please remember…UV light can damage your eyes.

Never point TFC’s UV Light Sabre at anyone and always protect your eyes – In fact we recommend that you do not sit and watch the TFC’s UV Light Sabre as you dry resin.

When curing resins, simply set the TFC’s UV Light Sabre in place, hold it steady and then avert eyes.

“Light Curing Resins – By Martin Jorgensen:

If you’re still messing around with two-component epoxy, it’s about time to lift your head from the vice and discover the new Light Curing Resins also known as LCR’s or UV Resins.

I’ve written about light curing resins before – also before I got to use it myself – and have been fascinated by the concept from the day I heard of it. My practical use has just made this fascination bigger. They’re smart!

They’re smart! TFC’s UV Light Sabre TFC’s UV Light Sabre TFC’s UV Light Sabre TFC’s Light Sabre

I think the technology – or the chemistry – comes from the dental world, where stuff like this is used to fix teeth. The idea of not having a prolonged working period, no “deadline”, not having heat develop while curing as well as working with something that isn’t inherently toxic probably appeals even more to dentists than it does to fly tyers.

And that actually sums up the advantages of these new glues, bonds, resins or whatever you prefer to call them:

- They cure in seconds when you want it and not before.

- They only cure under a special light, so you can work with them as long as you want.

- Heat often develops when epoxy cures. Not a big issue for fly tyers, but there’s no heat here.

- They seem to be significantly less harmful to you and the environment compared to epoxy.

- They are supposed to stay clear where epoxy often turns yellow.

- The glass hard versions seem to be less prone to cracking than epoxy.

- They are often referred to as LCR’s – Light Cured Resins.

- The process:TFC’s UV Light Sabre TFC’s UV Light Sabre TFC’s UV Light Sabre TFC’s Light Sabre.

For those who haven’t tried these resins, here’s the quick introduction.

You tie you fly as you normally would if you were to use epoxy. The steps where you apply epoxy are just replaced with applying LCR.

Most products come in small bottles or syringes, and have fine tips, which makes it easy to apply on even very small flies. You can use the tip of the bottle to distribute it and build up the shape you want, or you can use a dubbing needle if that suits you better. There is no mixing or preparation process, but the compounds are used right out the bottle.

There are different viscosities, but most are much like mixed epoxy: fluid, but with a high viscosity and pretty slow to “run”. This makes it easy to distribute the compound on the fly, and by rotating and tipping the fly, you can get it to run where you want it. Unlike epoxy this maneuver can last as long as you want. As soon as the shape is as you want it, you shine a special light on the bond, mostly from a small flashlight-like lamp, which emits UV or a special blue light, and the resin sets and hardens in seconds. So you don’t need an epoxy rotor either.

Once it’s cured the fly is ready to fish – or ready to have further materials added. There’s no waiting for it to fully harden or set. The hardening process usually lasts a few seconds or maybe 15-30 seconds for the thickest applications.

Viscosity: TFC’s UV Light Sabre TFC’s UV Light Sabre TFC’s UV Light Sabre TFC’s Light Sabre

You can apply several layers if you want, and build up the shape you want. You can even combine the different varieties of the same product and use special coating resins for the last layer.

Many brands come in different viscosities: thicker for building up volume and thinner for penetrating material or using as a varnish. Some of the products on the market also come in a flexible version that cures to a more rubbery feel, much like hot melt glue.

Thanks to the quick curing, you can use it for gluing on eyes, gill plates and even other materials like flash, feathers and hair. Look at Pete Gray’s ingenious welded flies to see how he builds up flies using LCR and no thread.”

Advantages:

Apart from the much more controllable process of curing, LCR’s have several advantages over epoxy, hot melt glue and silicone.

No waste – this is a real treat for the ones of us who have mixed endless batches of epoxy, used a third and seen the rest go hard. Slow curing 30 minute or one hour epoxy can improve on that, but also means turning your fly tying into a factory, producing many flies and coating them all a once.

Any shape – epoxy does enable the crafty tier to build up all kinds of shapes, but it requires many layers and a lot of skill and patience. With LCR’s you can build up almost any shape layer by layer, with intermittent curing.

Useful in really small amounts – you can use this for midge and buzzer bodies, nymph wing cases and applications on really small flies, where you only need a tiny drop. Apply that drop, cure and you’re set.

Available in different hardnesses – many of the products are available in several variations, from rubbery to glass hard.

No yellowing – according to most manufacturers LCR’s don’t turn yellow over time. Epoxy manufacturers may say the same, but epoxy usually does turn yellow. Time will tell whether LCR’s actually do stay clear.

Not as brittle – the LCR’s should be less prone to cracking or shattering when flies hit rocks or are used under cold conditions. Of course the hard resins are more vulnerable than the soft ones.

Less harmful – all the regulatory commissions in the US and in other countries are giving favorable considerations to UV technology. It dramatically reduces VOCs (Volatile Organic Compounds – harmful vapors) and exposure to allergens and toxins.

Tacky or sticky:

Some of the LCR’s are slightly sticky or tacky after having cured. They are not so gooey that material will stick to them, but you can feel the tackiness and the flies can stick to each other or hard surfaces when stored for longer periods.

There are two ways to avoid this:

Rub the resin covered part of the flies with alcohol (hand sanitizer with about 60% alcohol is often recommended). This will matte the resin, but make it hard and “dry”.

Add a final thin coat of a fluid and hard curing layer of resin (coat, finish or whatever the manufacturers call it) when the fly is done. This will cure much harder than the high viscosity resin, and won’t stick.

Not any lamp:

Each type of resin requires a specific wavelength of light to cure. There are essentially two types: UV and blue light. In general these are both considered harmless if you avoid shining very bright lamps directly into the eyes. You typically buy the lamps that’s designed to work with your choice of resin to ensure that it cures properly. You can switch lamps between some brands, but if you want to be sure, use the light that the manufacturer recommends.

Lights are available as small, battery driven flashlights AKA torches, large lamps to plug into the socket and some really bright and powerful lamps used by medical and industrial operations. Some manufacturers also supply screw-in bulbs for mounting in normal lamps. They all do the same job, but smaller lamps seem to take longer time to cure the same amount of resin. The big ones are – not surprisingly – better at penetrating thick layers of resin. Make sure that you use fresh batteries or rechargeable cells in the torches. The power of the light is essential to a good curing process.

I have only used the smallest flashlight type, and it has worked fine for me on all my flies, large and small. The curing time is typically a few seconds, maybe up to half a minute for thicker applications.”

Contact us for ordering details of TFC’s UV Light Sabre.

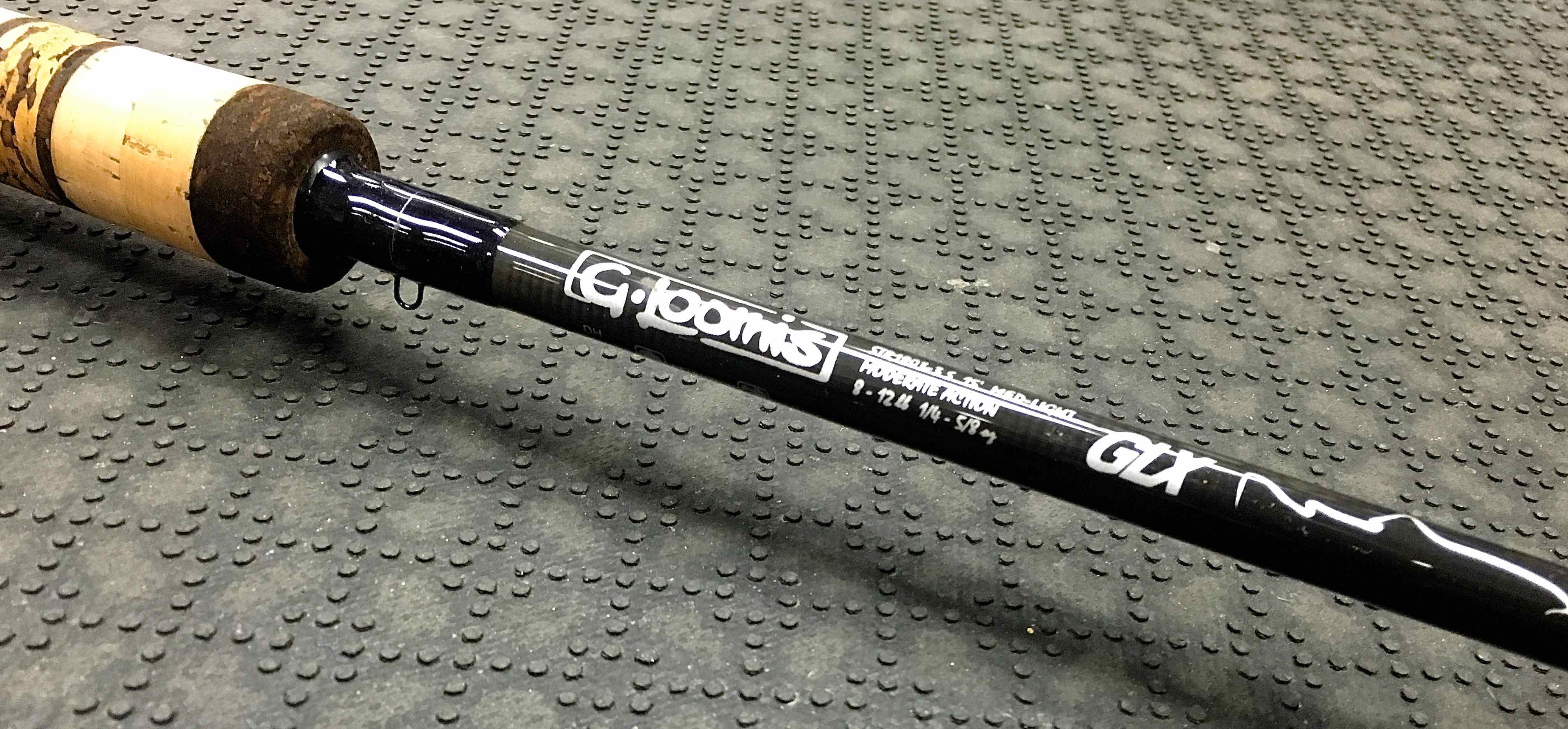

We are the leading provider of Fly Fishing Lessons, Corporate Team Building, and Guiding on the Upper Grand River, the Upper Credit River, and the Conestogo River.

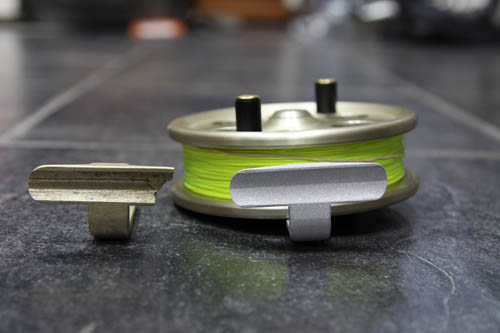

No Guelph, Fergus, Kitchener or Cambridge Fishing Tackle Retailer will boast as complete and diverse a store inventory, including a vast selection of Centerpin / Float Fishing Reels, Rods, Clothing and Accessories.

Order a HLS or TFC Gift Card – We will put one in the mail for FREE!